Understanding the Various Types of Moisture Meters and Their Applications

Understanding the Various Types of Moisture Meters and Their Applications

Blog Article

The Ultimate Guide to Wetness Meters: A Comprehensive Introduction and Exactly How They Can Conserve You Cash

Moisture meters serve as important tools in detecting and monitoring moisture material in products, assisting in stopping pricey damages and making certain the high quality of items. Understanding the subtleties of different kinds of dampness meters, their applications, and the possible cost-saving advantages they offer can be a game-changer for experts and services alike.

Kinds Of Dampness Meters

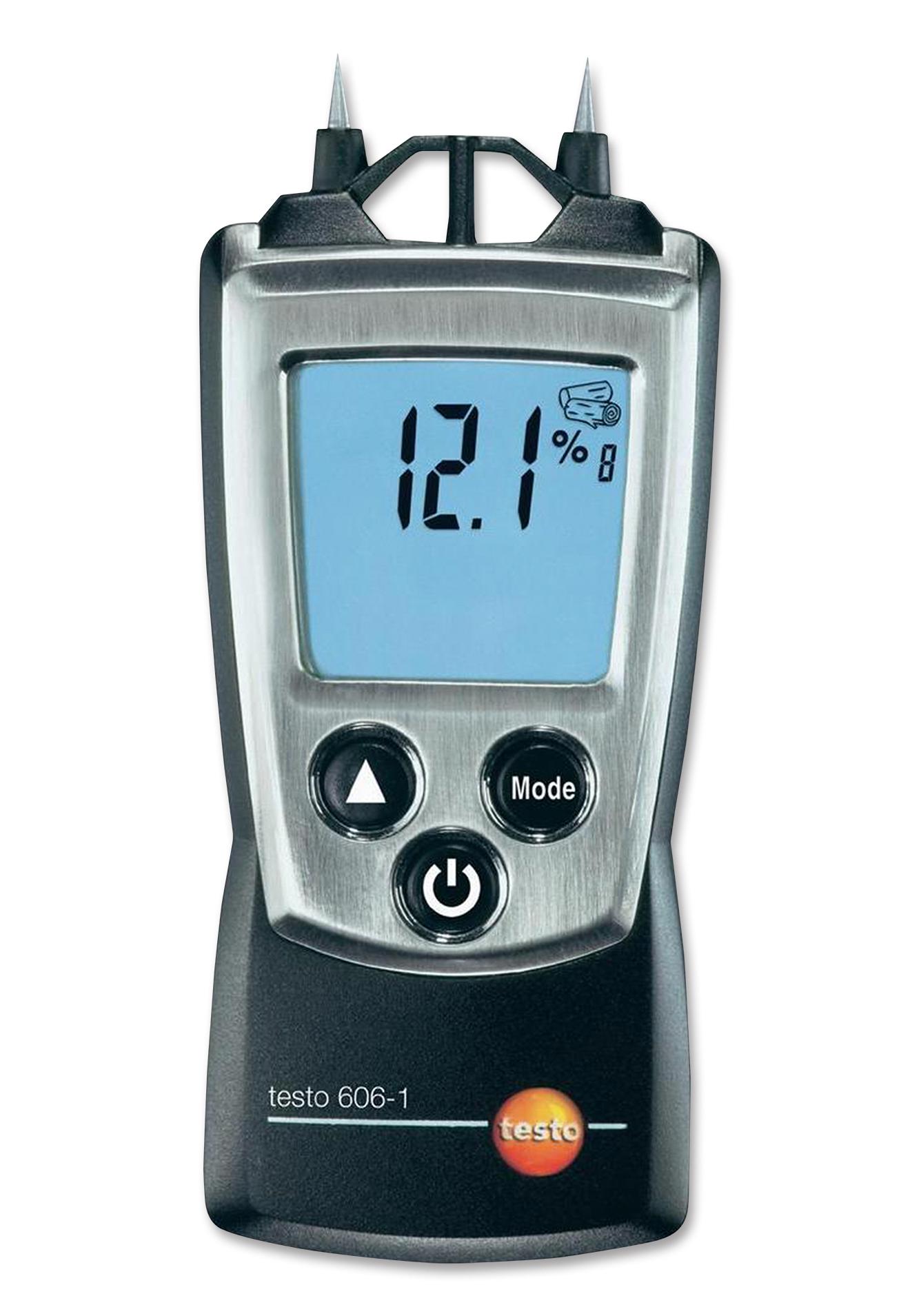

Numerous types of wetness meters are offered for various applications in different industries. One typical type is the pin-type moisture meter, which gauges the electrical resistance between 2 pins placed right into a material. This kind is suitable for wood, drywall, and other building products. Pinless dampness meters, on the other hand, use electro-magnetic sensing unit plates to scan a bigger area without triggering damage to the material's surface area. Moisture Meter. These meters are excellent for promptly examining dampness levels in large locations such as floorings and wall surfaces.

Infrared moisture meters determine the thermal residential or commercial properties of a product to establish its wetness material non-invasively, making them helpful for applications where pin or pinless meters may not be suitable. Comprehending the various kinds of wetness meters offered can help markets choose the most proper device for their particular moisture measurement needs.

Benefits of Utilizing Dampness Meters

Dampness meters offer indispensable advantages in properly analyzing and checking wetness levels in diverse products and atmospheres (Moisture Meter). One of the key benefits of using dampness meters is the prevention of potential damages brought on by excess wetness. By detecting and resolving high dampness levels early, wetness meters aid to avoid mold development, rot, and architectural damages in buildings, saving both time and cash on fixings. Additionally, wetness meters help in making sure the top quality of materials throughout building or manufacturing processes. By properly measuring moisture content, these tools aid keep the stability of wood, drywall, concrete, and other products, minimizing the threat of failures or issues.

In addition, utilizing wetness meters can result in boosted energy efficiency. By determining locations with high moisture degrees, such as leakages or inadequate insulation, modifications can be made to improve power preservation and decrease utility prices. In farming setups, dampness meters play a crucial role in maximizing plant returns by allowing farmers to keep an eye on soil dampness degrees and make educated watering decisions. On the whole, the benefits of using moisture meters cover across different sectors, giving cost-efficient solutions and promoting much better quality assurance techniques.

How to Pick the Right Wetness Meter

Picking the proper dampness meter includes taking into consideration vital factors such as product compatibility, measurement range, and calibration precision. When choosing a moisture meter, it's vital to guarantee that the meter appropriates for the specific material you will certainly be testing. Various materials have varying electric residential properties that can influence wetness readings, so selecting a meter made for your material is vital for precise results. In addition, consider the measurement array of the moisture meter. Ensure that the meter can find dampness levels within the range needed for your applications. Calibration precision is one more crucial variable to bear in mind. Select a dampness meter with trustworthy calibration to make certain constant and specific analyses. Some meters may need periodic calibration adjustments, so comprehending the calibration process is essential. By carefully evaluating these factors, you can pick a moisture meter that fulfills your demands and provides precise wetness measurements for your tasks.

Correct Techniques for Moisture Meter Usage

Cost Cost Savings With Dampness Meter Applications

How can the strategic application of moisture meters lead to significant cost financial savings across numerous markets? In the agriculture industry, dampness meters help in establishing the optimum time for harvesting crops, avoiding excess or over-drying dampness that can influence the last item's high quality.

Likewise, in building, wetness meters aid protect against expensive damages by spotting wetness levels in building products, such as timber or concrete, which can cause architectural issues if not attended to find here without delay. By recognizing issue locations early, contractors can take rehabilitative steps to prevent comprehensive fixings or substitutes, inevitably saving money and time.

Additionally, in the food handling industry, moisture meters are important for keeping an eye on product high quality and guaranteeing conformity with safety and security policies. By precisely measuring moisture material in food items, manufacturers can avoid wasting, preserve quality, and decrease waste, resulting in considerable price savings. Overall, the calculated application of wetness meters is an important investment that can bring about considerable price decreases and boosted performance throughout numerous industries.

Conclusion

In verdict, wetness meters are valuable devices for determining and detecting wetness levels in various materials. By using the ideal wetness meter and complying with correct strategies, customers can properly stop costly problems created by excess wetness. Purchasing a high quality dampness meter can bring about significant cost savings over time by recognizing potential problems early and investigate this site allowing timely remediation. Ultimately, dampness meters are crucial tools for maintaining the honesty and durability of materials and frameworks.

Wetness meters serve as crucial tools in finding and keeping track of moisture web content in materials, helping in protecting against costly problems and guaranteeing the top quality of items. Infrared dampness meters gauge the thermal residential or commercial properties of a product to identify its moisture content non-invasively, making them helpful for applications where pin or pinless meters might not be appropriate.Moisture meters use very useful benefits in accurately checking and examining dampness degrees in diverse products and settings. In farming setups, wetness meters play an important duty in enhancing crop returns by allowing farmers to check soil moisture levels and Check Out Your URL make educated irrigation decisions.In verdict, wetness meters are beneficial devices for spotting and gauging wetness levels in various materials.

Report this page